Full range of works in design, manufacture and maintenance service of tooling

Due to the GAZ production system, all processes at Dies and Molds Plant are absolutely transparent and clearly controlled, which makes it possible to forecast and guarantee order completion dates.

The plant has a certificate of compliance of the quality management system with the international standard ISO 9001:2008.

Dies and Molds Plant capabilities:

- complex solution — design support, measurements, 2D- and 3D-designing and simulation, technological process development, manufacture of the whole set of tooling and checking fixtures, strict quality control at all stages, online monitoring of manufacturing process, tooling set-up on the customer’s equipment, maintenance support, warranty service;

- easy communication — the fastest possible response to an inquiry, coordination and clarification with minimal time loss, quick resolution of any disputable issues, emergency repair;

- optimal cost — the price of tooling is actually determined by the customer based on their budget and expected modes of operation, maximum transparency of pricing, minimum losses in operation of tooling.

Tooling production – dies and molds

Technological capabilities of Dies and Molds Plant enable to produce high quality tooling up to 50 tons in a short time. The equipment fleet of the company has more than 1000 units of the core equipment, including high-speed five-axis machining centers with a operation area up to 6,000 x 4,000 x 3,000 mm. To fit and set up the dies, we have more than 30 presses up to 1,500 tons and table sizes up to 5,000 х 2,600 mm.

Our production is equipped with modern equipment for processing model materials and electrical discharge equipment: punching and wire-cut EDM machines, coordinate measuring machines (Mauser, Zeiss and Mora), electric overhead cranes with lifting capacity up to 50 tons.

Dies and Molds Plant has capabilities in production of special tooling: cutting, measuring, and bench-work tools, fasteners, dies, electrodes, fixtures, etc.), special-purpose equipment, benches, in-line transportation automatic lines, etc., as well as components and assembly units, namely:

- special metal-cutting tools: drills, taps, countersinks, reamers, cutters, mills of all kinds, broaches, etc.;

- special measuring tools: plugs, fixed gauges, c-type calipers, spline gauges, involute gauges;

- checking fixtures, fastening tools, bench-work tools, electrodes, marking dies, etc.;

- assembly lines: welding lines, machining automatic lines and robotic complexes;

- collecting conveyors: chain conveyors, apron conveyors, belt conveyors, roller conveyors, etc.,

- equipment and stands for riveting, pressing-in, trial, adjustment;

- machines: transportation automatic lines of various types and modifications,

- auxiliary tools (for milling, drilling, semi-finish drilling, finish drilling, thread-cutting, tube bending), welding tools (welding tongs, guns and torches), welding machines, welding jigs, individual assembly units and components of equipment.

Tooling maintenance and repair

Even the most careful use of tooling is not able to prevent progressive loss in appearance quality of the product manufactured with this tooling. The main advantage of maintenance and repair is that the cost of defect elimination is much cheaper than buying a new tooling.

In case your tooling requires repair (no matter where it was made), our specialists are ready to provide high-quality repair and maintenance services, which will allow you to avoid downtime of expensive equipment and decrease in its productivity.

Production of parts and blanks

Dies and Molds Plant produces technically complex products. Our equipment allows to process parts of any accuracy level and large dimensions up to 6,000 x 4,000 x 3,000 mm. The company has machining, heat treatment, and chemical heat treatment capabilities.

Development of design documentation and 3D modelling

Our own engineering center equipped with 30 workstations with modern CAD/CAM/CAE systems, has extensive experience in design of all kinds of tooling. The specialists of the engineering center develop design documentation, perform 3D simulation, and create control programs for CNC machines.

- Development of 3D models and parts.

- Development of design documentation for tooling.

- Development control programs for CNC machines.

- CMM measuring with accuracy up to 0,005 mm.

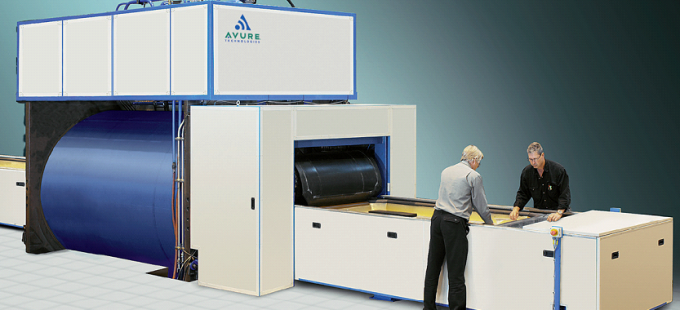

Fluid cell sheet metal forming

Quintus FlexForm or fluid cell sheet metal forming is a modern technology of prototyping and small and medium series production, which allows to achieve high quality of products at minimal costs for tooling and further processing. We provide a full production cycle for prototypes and small series of stamped products.

Partners

The company is focused on systematic and long-term cooperation with both leading international corporations and individual entrepreneurs.

Clients and committed partners of Dies and Molds Plant are the largest Russian and global manufacturers: