Fluid cell sheet metal forming - high quality products at minimal costs for tooling

Dies and Molds Plant is using the technology of fluid cell sheet metal forming Quintus FlexForm. This modern technology of prototyping and small and medium series production enables high quality products to be achieved at minimal costs for tooling and subsequent finishing.

In order to ensure the full production cycle of prototypes and small series of stamped products, we created a worksite with a five-axis laser cutting machine and coordinate measuring machine. The low cost of the matrix (rigid tool half) and its short manufacturing lead-time are the main factors making the technology of fluid cell forming an optimal solution for single-piece and small series production of high quality sheet metal products with maximum dimensions of 1,800 x 3,600 x 350 mm and metal thickness of 0.5-15 mm.

Quintus FlexForm – fuel cell forming system

- Availability of such a press at the specialized plant allows to place a consolidated order both for tooling (design and production) and manufacture of parts.

- Table dimensions unique for the Russian industry give the possibility to produce large-sized products + saving due to table utilization.

TECHNOLOGY OF FLUID CELL SHEET METAL FORMING

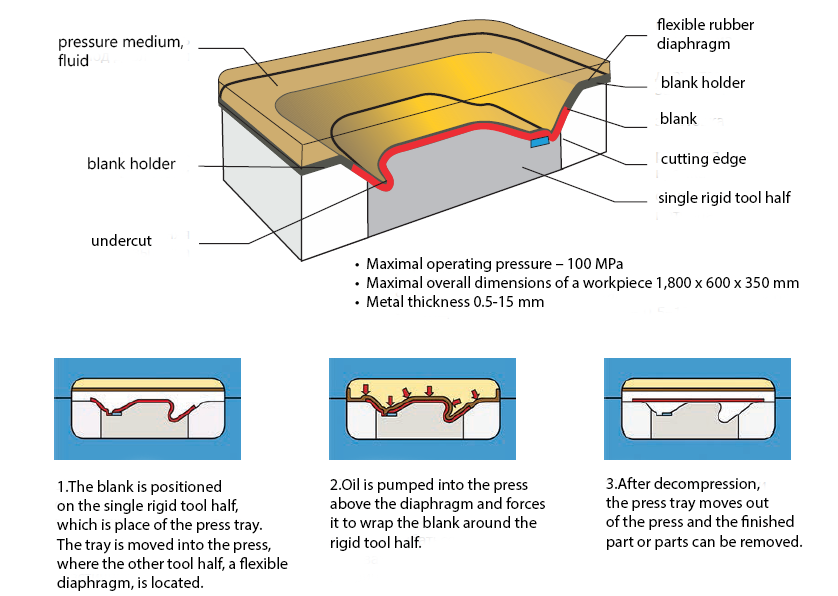

During fluid cell forming, the metal sheet adopts the shape of a single-sided rigid matrix under the force of an elastic rubber diaphragm, which surface is under the pressure of liquid.

High accuracy of matching with the matrix shape is achieved due to hydrostatic compression of the sheet, i.e. the applied pressure is the same at all areas of the surface and does not depend on the shape of the surface.

The principle of fluid cell forming